Quality

Innovative solutions

We firmly believe that quality is the foundation of our work, and that success is the natural outcome of consistent commitment carried out with passion and dedication.

Our corporate policy is centered on ensuring Total Quality. To achieve this goal, we have continuously embraced innovative solutions, the result of years of experience and research, enabling us to maintain the highest standards of excellence.

Quality

Innovative solutions

We firmly believe that quality is the foundation of our work, and that success is the natural outcome of consistent commitment carried out with passion and dedication.

Our corporate policy is centered on ensuring Total Quality. To achieve this goal, we have continuously embraced innovative solutions, the result of years of experience and research, enabling us to maintain the highest standards of excellence.

Quality

Innovative solutions

We firmly believe that quality is the foundation of our work, and that success is the natural outcome of consistent commitment carried out with passion and dedication.

Our corporate policy is centered on ensuring Total Quality. To achieve this goal, we have continuously embraced innovative solutions, the result of years of experience and research, enabling us to maintain the highest standards of excellence.

Quality as a Guiding Principle

Perfection, Our Goal

Quality is not only about process control and final product inspection: it is embedded in every stage of our work. Our primary commitment is always to achieve the highest level of perfection, with the goal of reaching zero defects. Eredi Baitelli adopts an integrated Industry 4.0 approach, constantly investing in advanced production technologies and automation to improve the work environment, enhance production capabilities, and expand business opportunities.

The selection of raw materials is a crucial aspect for us: we purchase exclusively and directly from established European suppliers.

A continuous investment program allows us to maintain a state-of-the-art, constantly updated machine fleet, paired with a rigorous program of meticulous maintenance to ensure optimal performance and a high CPK.

Our Priorities:

- Excellence in finished product quality

- Absolute punctuality in deliveries

- Strict commitment to honoring agreements

- High quality and operational standards

- Complete customer satisfaction

Quality as a Guiding Principle

Perfection, Our Goal

Quality is not only about process control and final product inspection: it is embedded in every stage of our work. Our primary commitment is always to achieve the highest level of perfection, with the goal of reaching zero defects. Eredi Baitelli adopts an integrated Industry 4.0 approach, constantly investing in advanced production technologies and automation to improve the work environment, enhance production capabilities, and expand business opportunities.

The selection of raw materials is a crucial aspect for us: we purchase exclusively and directly from established European suppliers.

A continuous investment program allows us to maintain a state-of-the-art, constantly updated machine fleet, paired with a rigorous program of meticulous maintenance to ensure optimal performance and a high CPK.

Our Priorities:

- Excellence in finished product quality

- Absolute punctuality in deliveries

- Strict commitment to honoring agreements

- High quality and operational standards

- Complete customer satisfaction

Quality as a Guiding Principle

Perfection, Our Goal

Quality is not only about process control and final product inspection: it is embedded in every stage of our work. Our primary commitment is always to achieve the highest level of perfection, with the goal of reaching zero defects. Eredi Baitelli adopts an integrated Industry 4.0 approach, constantly investing in advanced production technologies and automation to improve the work environment, enhance production capabilities, and expand business opportunities.

The selection of raw materials is a crucial aspect for us: we purchase exclusively and directly from established European suppliers.

A continuous investment program allows us to maintain a state-of-the-art, constantly updated machine fleet, paired with a rigorous program of meticulous maintenance to ensure optimal performance and a high CPK.

Our Priorities:

- Excellence in finished product quality

- Absolute punctuality in deliveries

- Strict commitment to honoring agreements

- High quality and operational standards

- Complete customer satisfaction

Metrology lab:

measurement equipment

Our metrology lab, recently upgraded, features some of the best equipment currently available on the market:

- PRESETTING MACHINE PRESET E236+

- PROFILE PROJECTOR HELIOS 350.H25

- OPTICAL MEASURING MACHINE OGP HOMMEL OPTICLINE CONTOUR C305

- SURFACE ROUGHNESS TESTER ZEISS SURFCOM 1500 SD

- 3D/OPTICAL COORDINATE MEASURING MACHINE ZEISS O-INSPECT

- HARDNESS TESTER GALILEO ERGOTEST DIGI 25 R

- OPTIKA MICROSCOPE

Our Quality Managers perform regular in-process sampling, using inspection benches with Marposs software and Mitutoyo measuring instruments, to ensure that every operation strictly meets the required parameters.

The entire production process is fully computerized, ensuring fast and accurate information exchange between all departments and, above all, full traceability at every stage.

At every machine start-up, our quality specialists carry out thorough inspections and, as part of the standard cycle, provide first-off samples in accordance with the requirements of the Level 3 Production Part Approval Process (PPAP).

We can provide any quality documentation the Customer may require:

PPAP – all submission levels, Cp/Cpk analysis, FMEA, MSA, IMDS, 8D, 5 Whys analysis, Ishikawa diagram.

We always guarantee full traceability of raw materials for all our Customers. Upon request, we can perform 100% inspection with any type of report, properly documenting the quality checks carried out on the entire batch.

Metrology lab:

measurement equipment

Our metrology lab, recently upgraded, features some of the best equipment currently available on the market:

- PRESETTING MACHINE PRESET E236+

- PROFILE PROJECTOR HELIOS 350.H25

- OPTICAL MEASURING MACHINE OGP HOMMEL OPTICLINE CONTOUR C305

- SURFACE ROUGHNESS TESTER ZEISS SURFCOM 1500 SD

- 3D/OPTICAL COORDINATE MEASURING MACHINE ZEISS O-INSPECT

- HARDNESS TESTER GALILEO ERGOTEST DIGI 25 R

- OPTIKA MICROSCOPE

Our Quality Managers perform regular in-process sampling, using inspection benches with Marposs software and Mitutoyo measuring instruments, to ensure that every operation strictly meets the required parameters.

The entire production process is fully computerized, ensuring fast and accurate information exchange between all departments and, above all, full traceability at every stage.

At every machine start-up, our quality specialists carry out thorough inspections and, as part of the standard cycle, provide first-off samples in accordance with the requirements of the Level 3 Production Part Approval Process (PPAP).

We can provide any quality documentation the Customer may require:

PPAP – all submission levels, Cp/Cpk analysis, FMEA, MSA, IMDS, 8D, 5 Whys analysis, Ishikawa diagram.

We always guarantee full traceability of raw materials for all our Customers. Upon request, we can perform 100% inspection with any type of report, properly documenting the quality checks carried out on the entire batch.

METROLOGY LAB:

MEASURING EQUIPMENT

Our recently updated metrology lab is equipped with the best currently available machines:

- PROFILE PROJECTOR HELIOS 350.H25

- OPTICAL SHAFT MEASURING SYSTEM OGP HOMMEL OPTICLINE CONTOUR C305

- ROUGHNESS TESTER ZEISS SURFCOM 1500 SD

- OPTICAL MULTI-SENSOR MEASURING MACHINE ZEISS S O-INSPECT

- HARDNESS TESTER GALILEO ERGOTEST DIGI 25 R

- MICROSCOPE OPTIKA

During the production process, our quality managers perform regular sample checks to ensure that the defined standard parameters are permanently maintained. For our quality checks we employ control desks equipped with Marposs software and Mitutoyo measuring devices.

In order to allow an efficient and prompt exchange of information between the involved internal divisions, and to enable us to supervise and trace every single production phase, we have implemented full process computerization.

All production phases are specified in detail and the staff dedicated to quality performs a full check at every machine start. As a standard cycle, we deliver samples of the production start following PPAP level III.

We can provide our customers any necessary quality report:

PPAP – all levels, CP/CPK, FMEA, MSA, IMDS, 8D and Five Whys Analysis as well as Ishikawa Diagrams.

Full traceability of raw materials is assured to all our customers. On request, we can perform 100% control and supply any required report containing all quality controls carried out on the production batch.

Metrology lab:

measurement equipment

Our metrology lab, recently upgraded, features some of the best equipment currently available on the market:

- PRESETTING MACHINE PRESET E236+

- PROFILE PROJECTOR HELIOS 350.H25

- OPTICAL MEASURING MACHINE OGP HOMMEL OPTICLINE CONTOUR C305

- SURFACE ROUGHNESS TESTER ZEISS SURFCOM 1500 SD

- 3D/OPTICAL COORDINATE MEASURING MACHINE ZEISS O-INSPECT

- HARDNESS TESTER GALILEO ERGOTEST DIGI 25 R

- OPTIKA MICROSCOPE

Our Quality Managers perform regular in-process sampling, using inspection benches with Marposs software and Mitutoyo measuring instruments, to ensure that every operation strictly meets the required parameters.

The entire production process is fully computerized, ensuring fast and accurate information exchange between all departments and, above all, full traceability at every stage.

At every machine start-up, our quality specialists carry out thorough inspections and, as part of the standard cycle, provide first-off samples in accordance with the requirements of the Level 3 Production Part Approval Process (PPAP).

We can provide any quality documentation the Customer may require:

PPAP – all submission levels, Cp/Cpk analysis, FMEA, MSA, IMDS, 8D, 5 Whys analysis, Ishikawa diagram.

We always guarantee full traceability of raw materials for all our Customers. Upon request, we can perform 100% inspection with any type of report, properly documenting the quality checks carried out on the entire batch.

OUR CUSTOMIZED SERVICES

OUR CUSTOMIZED SERVICES

Always convinced that the excellence of a company comes from the ability to partner clients in finding customized solutions, we guarantee the highest level in terms of precision, quality and on-time delivery. Our experience, the careful advisory from our sales and technical team combined with meticulous evaluation of all requests allow us to be extremely competent and reliable:

• We assist the customer during the whole production cycle. Our philosophy is Customer Orientation and Total Quality and is strongly based on results. For this reason, Eredi Baitelli conducts periodic surveys of the Customer Satisfaction Level, polling customers’ opinions and reviews in order to learn from their assessments.

• We offer personalized solutions: technical consultancy for product optimization, 100% control of the machined parts, security stock, full traceability of the entire production process, surface treatments, different packaging types, utmost delivery precision.

SATISFACTION INDEX

Based on our customers’ reviews, Eredi Baitelli’s staff receives the highest score of overall satisfaction; with ratings varying between 98.4 and 100%. The reference benchmarks are: delivery promptness, product quality especially on large production batches, cost transparency, willingness, cooperation, flexibility as well as environmental protection and safety.

OUR CUSTOMIZED SERVICES

Always convinced that the excellence of a company comes from the ability to partner clients in finding customized solutions, we guarantee the highest level in terms of precision, quality and on-time delivery. Our experience, the careful advisory from our sales and technical team combined with meticulous evaluation of all requests allow us to be extremely competent and reliable:

• We assist the customer during the whole production cycle. Our philosophy is Customer Orientation and Total Quality and is strongly based on results. For this reason, Eredi Baitelli conducts periodic surveys of the Customer Satisfaction Level, polling customers’ opinions and reviews in order to learn from their assessments.

• We offer personalized solutions: technical consultancy for product optimization, 100% control of the machined parts, security stock, full traceability of the entire production process, surface treatments, different packaging types, utmost delivery precision.

SATISFACTION INDEX

Based on our customers’ reviews, Eredi Baitelli’s staff receives the highest score of overall satisfaction; with ratings varying between 98.4 and 100%. The reference benchmarks are: delivery promptness, product quality especially on large production batches, cost transparency, willingness, cooperation, flexibility as well as environmental protection and safety.

OUR CUSTOMIZED SERVICES

Always convinced that the excellence of a company comes from the ability to partner clients in finding customized solutions, we guarantee the highest level in terms of precision, quality and on-time delivery. Our experience, the careful advisory from our sales and technical team combined with meticulous evaluation of all requests allow us to be extremely competent and reliable:

• We assist the customer during the whole production cycle. Our philosophy is Customer Orientation and Total Quality and is strongly based on results. For this reason, Eredi Baitelli conducts periodic surveys of the Customer Satisfaction Level, polling customers’ opinions and reviews in order to learn from their assessments.

• We offer personalized solutions: technical consultancy for product optimization, 100% control of the machined parts, security stock, full traceability of the entire production process, surface treatments, different packaging types, utmost delivery precision.

SATISFACTION INDEX

Based on our customers’ reviews, Eredi Baitelli’s staff receives the highest score of overall satisfaction; with ratings varying between 98.4 and 100%. The reference benchmarks are: delivery promptness, product quality especially on large production batches, cost transparency, willingness, cooperation, flexibility as well as environmental protection and safety.

EREDI BAITELLI AIMS

AT HIGH QUALITY THROUGH

AUTOMATED ORDER MANAGEMENT

—

SHIPMENTS IN 48 HOURS

AVERAGE OF

5 TRUCKS LEAVING EACH DAY

EREDI BAITELLI AIMS

AT HIGH QUALITY THROUGH

AUTOMATED ORDER MANAGEMENT

—

SHIPMENTS IN 48 HOURS

AVERAGE OF

5 TRUCKS LEAVING EACH DAY

EREDI BAITELLI AIMS

AT HIGH QUALITY THROUGH

AUTOMATED ORDER MANAGEMENT

—

SHIPMENTS IN 48 HOURS

AVERAGE OF

5 TRUCKS LEAVING EACH DAY

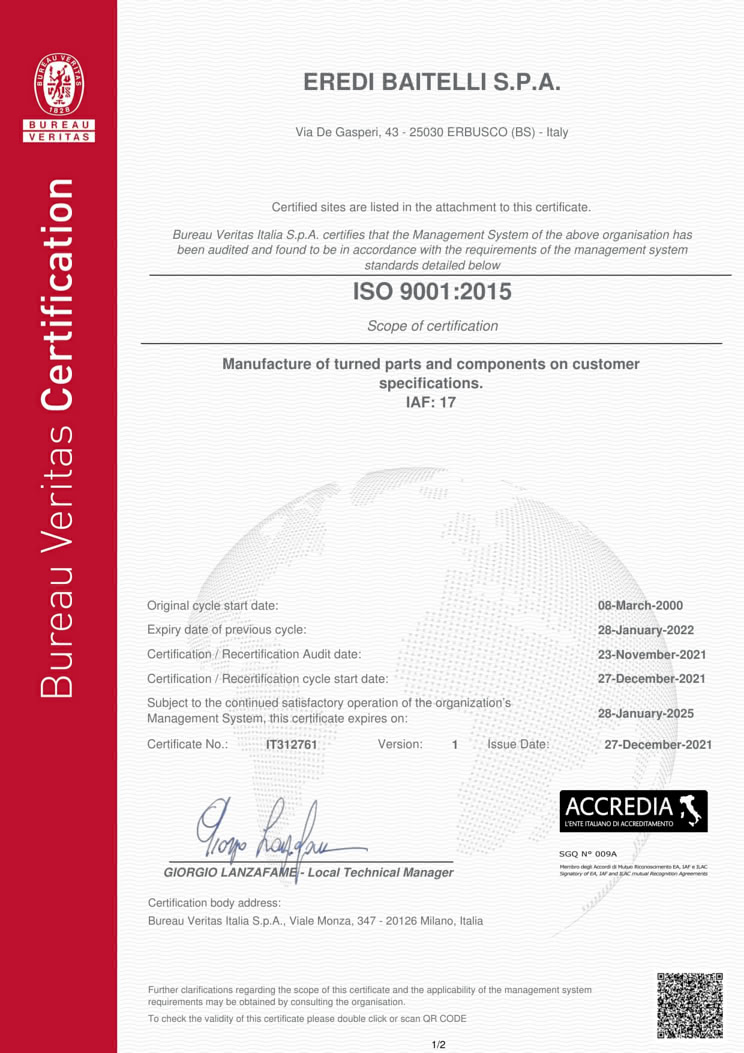

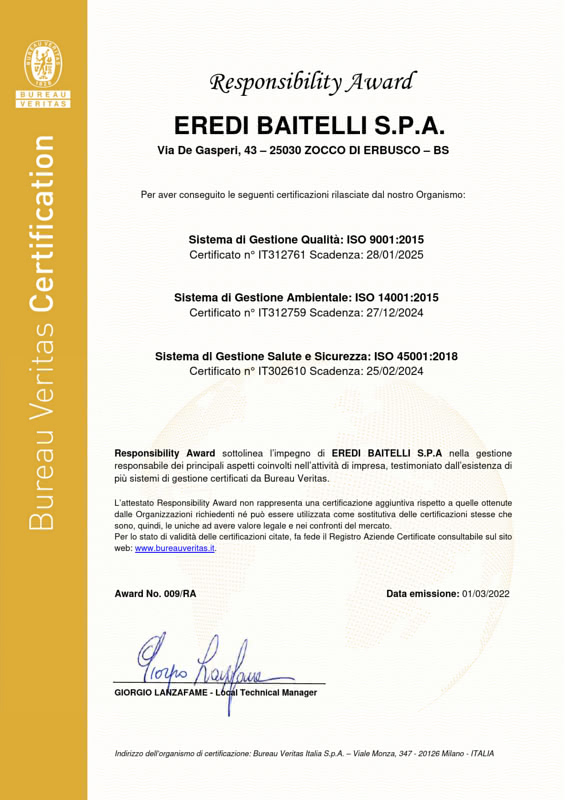

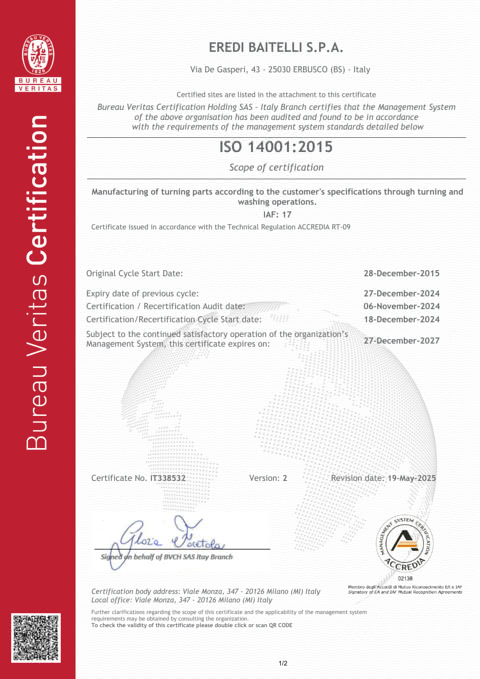

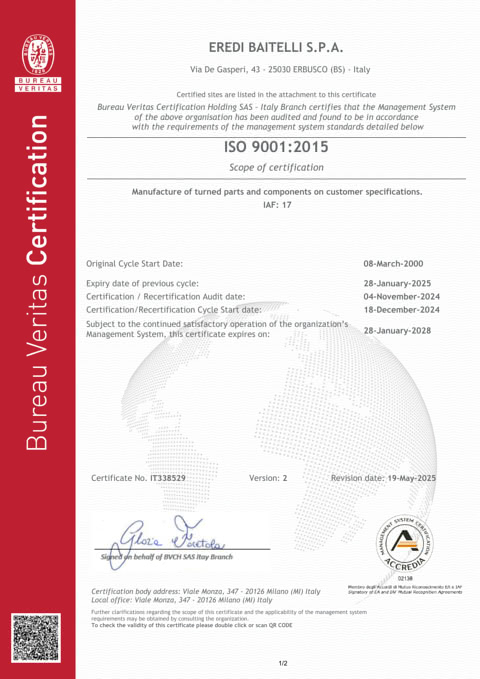

EREDI BAITELLI’S CERTIFICATIONS

Our company has built up the necessary resources over time, in terms of people, equipment and organization. This complete system generates the only recognized value: Quality. Obtaining and renewing certifications like UNI EN ISO 14001, UNI EN ISO 9001 and ISO 45001 related to Employee Safety and Health Management, which we observe and apply consistently, represent for our company not only a valuable recognition, but also a starting point for continuous improvement in order to achieve the world-wide success we are working towards.

Eredi Baitelli certifications

We have put in place the human, technical and organizational resources needed to guarantee the only value we truly recognize: Quality.

Our ISO 9001, ISO 14001 and ISO 45001 certifications confirm an integrated management system (quality, environment, and occupational health & safety) and reinforce our commitment to continuous improvement. Their scope covers the manufacture of turned parts and components to customer specifications.

In addition, Bureau Veritas’ Responsibility Award recognizes our commitment to responsible management.

Eredi Baitelli certifications

We have put in place the human, technical and organizational resources needed to guarantee the only value we truly recognize: Quality.

Our ISO 9001, ISO 14001 and ISO 45001 certifications confirm an integrated management system (quality, environment, and occupational health & safety) and reinforce our commitment to continuous improvement. Their scope covers the manufacture of turned parts and components to customer specifications.

In addition, Bureau Veritas’ Responsibility Award recognizes our commitment to responsible management.

UNI EN ISO

14001

UNI EN ISO

9001

ISO

45001

RESPONSIBILITY

AWARD

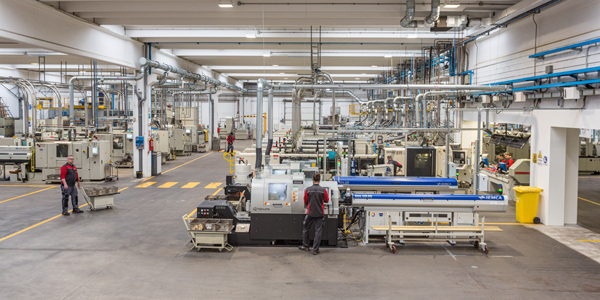

MACHINE-PARK

At Eredi Baitelli we continue to invest in technical trainings of our workforce and in capital equipment, because it is our intention to improve steadily: Our machine-park is refreshed frequently, in order to respond to the increasingly sophisticated and challenging demands of our customers in the most accurate and cutting-edge way.

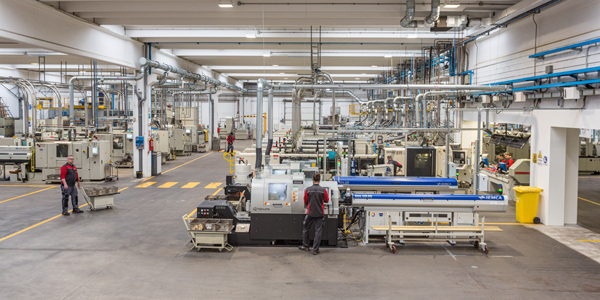

MACHINE-PARK

At Eredi Baitelli we continue to invest in technical trainings of our workforce and in capital equipment, because it is our intention to improve steadily: Our machine-park is refreshed frequently, in order to respond to the increasingly sophisticated and challenging demands of our customers in the most accurate and cutting-edge way.

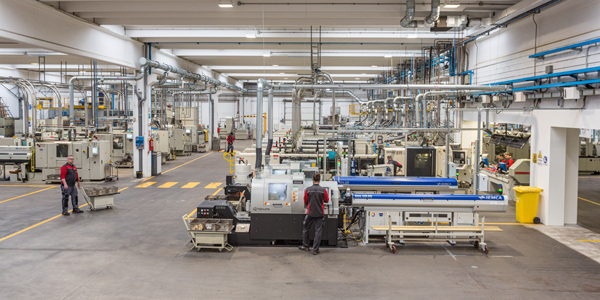

MACHINE-PARK

At Eredi Baitelli we continue to invest in technical trainings of our workforce and in capital equipment, because it is our intention to improve steadily: Our machine-park is refreshed frequently, in order to respond to the increasingly sophisticated and challenging demands of our customers in the most accurate and cutting-edge way.

The whole production process is connected to and managed by computer panels and is regularly updated.

MANUFACTURING FACILITY

Automatic multi-spindle lathes and classic single-spindles: Mori Say, Wickman, Schütte, Gildemeister, Hanwha, Tornos

The whole production process is connected to and managed by computer panels and is regularly updated.

MANUFACTURING FACILITY

Automatic multi-spindle lathes and classic single-spindles: Mori Say, Wickman, Schütte, Gildemeister, Hanwha, Tornos

The whole production process is connected to and managed by computer panels and is regularly updated.

MANUFACTURING FACILITY

Automatic multi-spindle lathes and classic single-spindles: Mori Say, Wickman, Schütte, Gildemeister, Hanwha, Tornos

WASHING FACILITY

Two metal cleaning machines based on modified alcohol solvents and one closed circuit washing plant. Thanks to our new automated and technologically advanced cleaning facility, we have optimized the operation of this important phase along with a significant reduction of manpower compared to the past. We have thus been able to increase our production and accelerate the subsequent stages of control, packing and shipment.

WASHING FACILITY

Two metal cleaning machines based on modified alcohol solvents and one closed circuit washing plant. Thanks to our new automated and technologically advanced cleaning facility, we have optimized the operation of this important phase along with a significant reduction of manpower compared to the past. We have thus been able to increase our production and accelerate the subsequent stages of control, packing and shipment.

WASHING FACILITY

Two metal cleaning machines based on modified alcohol solvents and one closed circuit washing plant. Thanks to our new automated and technologically advanced cleaning facility, we have optimized the operation of this important phase along with a significant reduction of manpower compared to the past. We have thus been able to increase our production and accelerate the subsequent stages of control, packing and shipment.

PACKING FACILITY

Piece counting and weight control systems.

PACKING FACILITY

Piece counting and weight control systems.

PACKING FACILITY

Piece counting and weight control systems.