80 Years of Precision, Continuity, and Commitment

Since 1945, across three generations, we have been dedicated to precision metal turning. Eighty years of industrial experience have made us a trusted reference point for those seeking reliability, flexibility, and expertise. The confidence placed in us by our Clients, both in Italy and abroad, is the most concrete proof of the quality of our products and our ability to respond promptly to the specific requirements of each project.

We have built our approach on a balance between technical tradition and continuous innovation. Every day we invest in people, technology, and organization to meet the challenges of an ever-evolving industry with clarity and preparation.

PASQUALE BAITELLI

Owner

80 Years of Precision, Continuity, and Commitment

Since 1945, across three generations, we have been dedicated to precision metal turning. Eighty years of industrial experience have made us a trusted reference point for those seeking reliability, flexibility, and expertise. The confidence placed in us by our Clients, both in Italy and abroad, is the most concrete proof of the quality of our products and our ability to respond promptly to the specific requirements of each project.

We have built our approach on a balance between technical tradition and continuous innovation. Every day we invest in people, technology, and organization to meet the challenges of an ever-evolving industry with clarity and preparation.

PASQUALE BAITELLI

Owner

OUR STORY

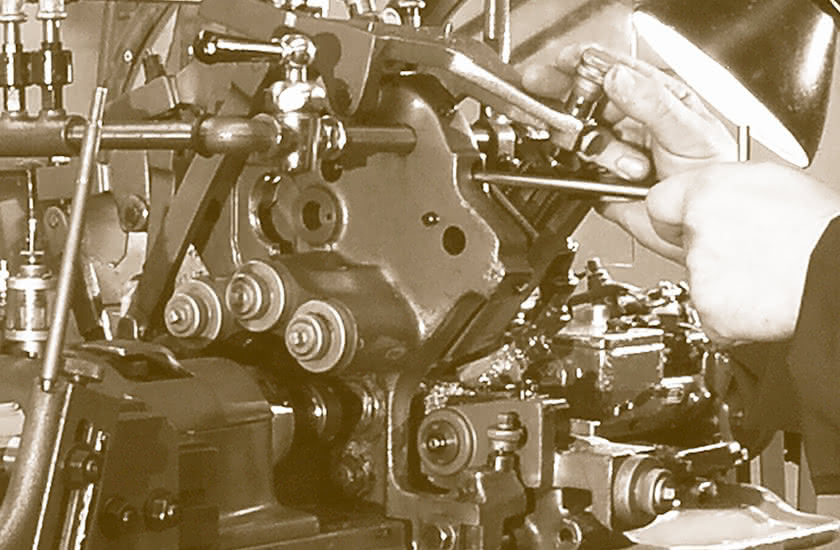

The origins

It was in Palazzolo sull'Oglio, in 1945, that Leopoldo Baitelli founded his precision engineering workshop.

The business was born out of the experience he had gained in previous years at Tornos SA in Moutier, Switzerland. This marked the beginning of a story of technical expertise, dedication, and industrial vision.

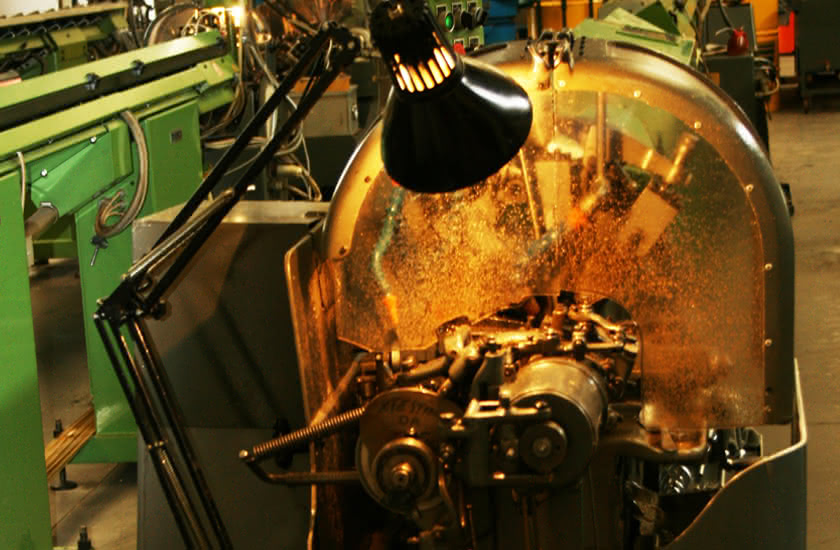

Expansion

The company grows and moves to larger premises, still in Palazzolo sull'Oglio.

The new workshop houses a line of automatic lathes, marking the beginning of a phase of structured and continuous industrial development.

The second generation

In 1968, Pasquale Baitelli joined the company, taking over from his father Leopoldo. He brought with him valuable technical experience gained in Moutier (Switzerland), once again at the prestigious Tornos SA. It was the beginning of a new phase that combined family continuity with a drive towards the future.

The new headquarters in Zocco di Erbusco

In 1990, the modern factory in Zocco di Erbusco (Brescia) was inaugurated, designed to house advanced production lines and ensure operational flexibility. This facility marked the beginning of a phase of technological and organizational growth, with large spaces dedicated to automatic lathes, safe work areas, and optimized internal flows.

ISO 9001 Certification

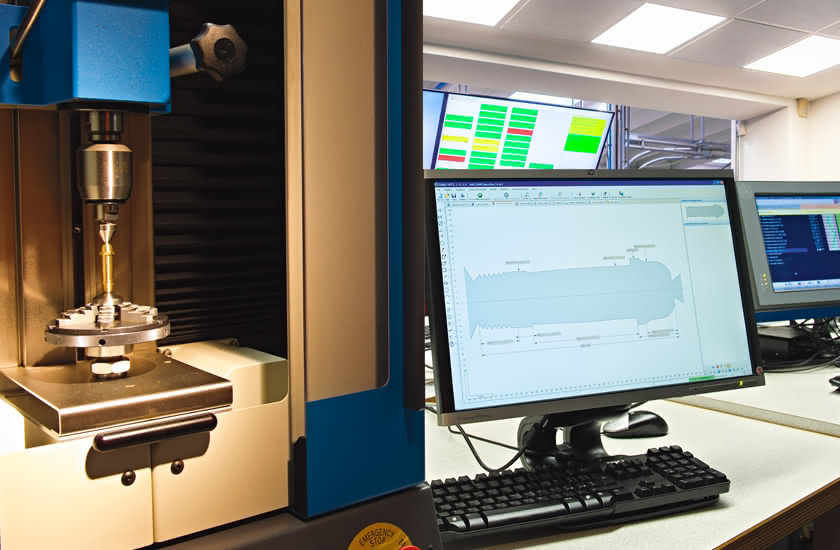

By obtaining UNI EN ISO 9001 certification, Eredi Baitelli formalizes its quality management system, integrating advanced measuring instruments and rigorous control procedures that still guide every stage of production.

Opening of the Rovato branch

Eredi Baitelli inaugurates a new branch in Rovato (Brescia). This location strategically supports the activities of the main headquarters in Zocco di Erbusco, strengthening logistics, production, and operational capabilities and improving customer service.

From family business to joint-stock company.

In 2008, Eredi Baitelli became a joint-stock company and embarked on a phase of strong internationalization: participation in trade fairs, global partnerships, and strategic investments strengthened the brand's position on world markets.

OHSAS 18001 Certification

Eredi Baitelli obtains OHSAS 18001 certification, consolidating its commitment to health and safety at work with structured processes and procedures.

ISO 14001 certification

Eredi Baitelli obtains UNI EN ISO 14001 certification, consolidating its environmental management and sustainability practices throughout the entire production process..

The third generation

In 2017, Matteo Baitelli, grandson of the founder and son of Pasquale, joins the team. With his modern training and passion for innovation, he marks a new chapter in the family history, ready to lead Eredi Baitelli towards future challenges.

Company merger

In 2018, Eredi Baitelli and Minuterie Eredi Baitelli merged into a single entity, strengthening their expertise and synergies to offer even more comprehensive solutions in the precision turning sector.

ISO 45001:2018 certification obtained

In 2020, Eredi Baitelli obtained UNI ISO 45001:2018 certification, confirming its commitment to ensuring the health and safety of its workers through structured processes and periodic checks.

The new site in Erbusco

In 2023, a modern production plant was launched in Erbusco (BS), designed to optimize flows, technologies, and operating spaces, consolidating the ability to respond to market needs with efficiency and flexibility.

EREDI BAITELLI IS MARKETING ORIENTED

MISSION

VALUES

PLUS

We create and deliver custom-made turned components that comply with the specifications provided, with maximum punctuality, operating in a careful and responsible manner towards people, the environment, and the market.

VALORI

- Best possible quality

- Technological innovations

- Production efficiency

- Attention to market requirements

- Environment preservation

- Work ethics

- Customer comes always first

- Consistent and verified quality

- Innovation as a daily habit

- Streamlined processes and fast turnaround times

- Listening to the market and responding quickly

- Concrete environmental sustainability

- Ethics and safety in the workplace

- Customer focus in every decision

PLUS

- Our method is team work

- 45 employees, median age: 38 years

- 150 million parts per year

- The production process is completely in-house: 100% made in Italy

- Continuous maintenance and update of our machine park

- Maximum production flexibility

- Recognition by major certifications

- Close-knit team of professionals

- 150 million pieces produced every year

- 100% internal supply chain: authentic Made in Italy

- Machinery fleet constantly updated and maintained

- Flexible production, from prototypes to large series

- ISO 9001, ISO 14001, and ISO 45001 certifications

INVESTMENTS

GLOBAL

MARKETING

INVESTIMENTI

In order to continuously develop innovative products for any industry and application field.

- Focus on new technologies

- Detail refinement

We upgrade our machinery and skills to reduce lead times, ensure the best quality, and be open to new applications in every sector.

GLOBALE

- We operate worldwide, on all 5 continents

- Export: 80% of our production

We ship to over thirty countries on five continents; exports account for 80% of production and are supported by dedicated logistics.

MARKETING

- Integrative global communication

- Multimedia services

- Sales support

Clear communication, digital tools, and targeted commercial support.

MISSION

We create and deliver custom-made turned components that comply with the specifications provided, with maximum punctuality, operating in a careful and responsible manner towards people, the environment, and the market.

VALUES

- Consistent and verified quality

- Innovation as a daily habit

- Streamlined processes and fast turnaround times

- Listening to the market and responding quickly

- Concrete environmental sustainability

- Ethics and safety in the workplace

- Customer focus in every decision

MISSION

VALUES

We create and deliver custom-made turned components that comply with the specifications provided, with maximum punctuality, operating in a careful and responsible manner towards people, the environment, and the market.

- Consistent and verified quality

- Innovation as a daily habit

- Streamlined processes and fast turnaround times

- Listening to the market and responding quickly

- Concrete environmental sustainability

- Ethics and safety in the workplace

- Customer focus in every decision

PLUS

- Close-knit team of professionals

- 150 million pieces produced every year

- 100% internal supply chain: authentic Made in Italy

- Machinery fleet constantly updated and maintained

- Flexible production, from prototypes to large series

- ISO 9001, ISO 14001, and ISO 45001 certifications

INVESTMENTS

We upgrade our machinery and skills to reduce lead times, ensure the best quality, and be open to new applications in every sector.

PLUS

INVESTMENTS

- Close-knit team of professionals

- 150 million pieces produced every year

- 100% internal supply chain: authentic Made in Italy

- Machinery fleet constantly updated and maintained

- Flexible production, from prototypes to large series

- ISO 9001, ISO 14001, and ISO 45001 certifications

We upgrade our machinery and skills to reduce lead times, ensure the best quality, and be open to new applications in every sector.

GLOBAL

We ship to over thirty countries on five continents; exports account for 80% of production and are supported by dedicated logistics.

MARKETING

Clear communication, digital tools, and targeted commercial support.

GLOBAL

MARKETING

We ship to over thirty countries on five continents; exports account for 80% of production and are supported by dedicated logistics.

Clear communication, digital tools, and targeted commercial support.